OVERVIEW

R & D

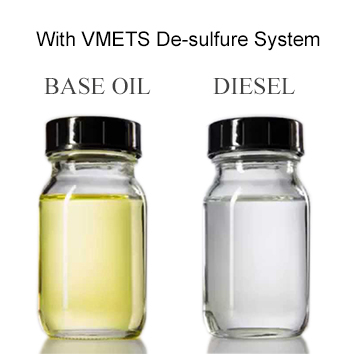

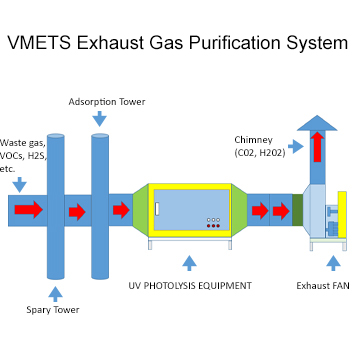

We have a strong R&D team to keep up to date with the latest market information and the latest technological developments. Our research and development team is able to integrate institutional, electric control, petroleum refining, waste oil regeneration, biodiesel , waste recycling, and other specialized fields, and continuously conducts application research with experts and investors from various countries to combine equipment development and market demand to provide the best products for our customers.

VMETS’s manufacturing department does not only sell complete equipment, but also offers the production and assembly of the best single-phase equipment on the market today. More than 20 skilled assembly technicians provide customers with the most precision-made products in a timely manner, with the highest standards and requirements in the world, and with quality assurance and correctness. Ende has currently undergone stringent domestic and international inspections and certifications, such as ISO: 9001 and ISO: 9002, CE and EPA.

Our featured

Support 24/7

Maintenance

Full services